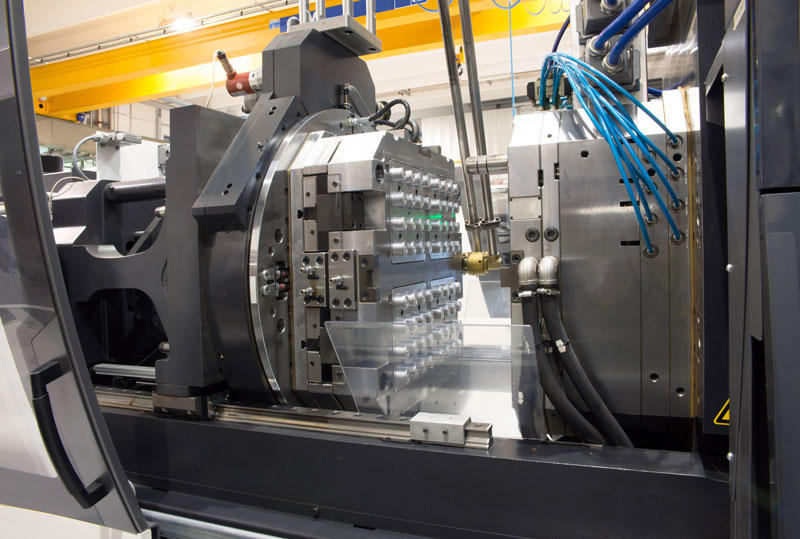

Thermoplastic injection moulding

All the machines in the company are automated. Dosage of material, dosage of colours, drying of materials, and sorting of products are carried out with automated peripheral units. The production program is based primarily on technically demanding products and a diverse range of materials.

The whole process – from the phase of development to the phase of production of plastic products – consists of:

Product design and development

Selection of materials

Tool construction and production

Sampling and at last, production

Injection of materials

We work on injections of the following materials:

- PP

- PBT

- PA, PA6

- PC

- POM

- ABS

- PE

Machinery

Our machinery comprises of injection moulding machines with clamping force from 30 to 150 tones.

Brands: Battenfeld/Wittmann (logo) and Krauss Maffei